Source: © PR Times, Inc.

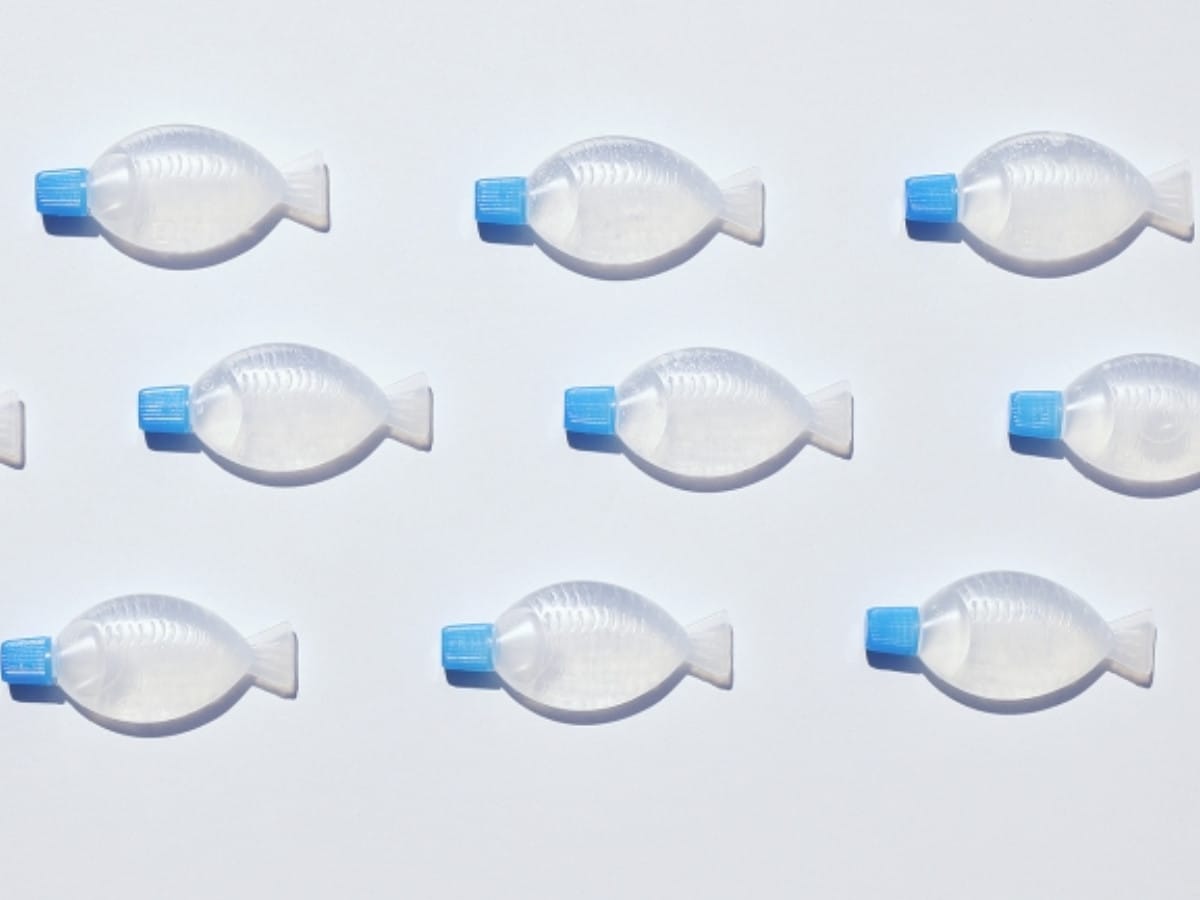

Repurposing Plastic Fish Soy Sauce Containers to Help Clean Up the Pandemic

- Tags:

- coronavirus / COVID-19 / Fish / hand sanitizer

Related Article

-

Care-Taking Goldfish Seems To Help Friend Who Struggles To Eat On Their Own

-

A growing number of ‘cyber homeless’ are struggling in Japan amid the pandemic

-

Nagano farmers and restaurants team up to provide home vegetable meals during pandemic

-

Tokyo event aims to raise awareness of difficulties deaf people face during the pandemic

-

Switch to teleworking prompts boom in ‘digicam-friendly’ clothing

-

Joban-Mono: The Most Delicious Fish In Japan Powering Fukushima’s Revival[PR]

Although a clean society, Japan does have some issues with waste. Rubbish sorting rules are notably detailed, and towns like Kamikatsu are stringent recyclers. Nevertheless, there is in an inordinate amount of hard-to-dispose-of plastic packaging. Sure there are recycling centers, but it remains unclear how much plastic material effectively re-enters the consumption cycle. For example, a large portion is shipped to other countries that may or may not handle it properly.

Indeed, even when enjoying a simple meal, consumers seem to end up with an entire bag full of plastic waste. Bento lunchboxes, for example, come in plastic boxes, with a plastic top, plastic containers and dividers, as well as a small plastic fish soy sauce container. However, during the coronavirus outbreak, there is a dropping demand for ready-made lunches and takeout dishes. Rather than toss all that plastic packaging, thrifty manufacturers have repurposed the iconic fish soy sauce container.

No More Takeout

Saitama-based Ohishiya manufactures small plastic fish containers. The petite bottle is filled with a single serving of soy sauce and topped with a red screw-on top. They most often come in bento boxes or takeout sushi packs, but are sometimes given to diners at restaurants. You can see them in action below. Apparently, there is also a novelty jumbo version available for beverages, although I’ve never seen it IRL.

As you can see, they are iconic and convenient. However, as the pandemic developed, consumers mostly stopped eating out as many restaurants closed throughout Japan. Restaurants and food vendors canceled their orders with Oshihiya, and the manufacturer was left with unmovable excess inventory.

Working Together

While one demand hand been wiped out by the pandemic, another had been created: the need for personal hygiene products, particularly hand sanitizer. Tokyo-based Clear Electron had begun selling sanitizer in March but to poor results. As an electronics firm, the company had no name recognition.

An advertiser suggested, however, that Ohishiya and Clear Electron could help solve one another's problems. The two companies teamed up and began offering much-needed hand sanitizer in the instantly recognizable fish containers.

According to the Japan Times, over 200,000 fish-shaped bottles have been repurposed to hold Clear Electrons hand sanitizer. After changing the cap color to blue, the bottles were distributed to eateries in Tokyo. Lest anyone should be confused, the hand sanitizer is made from natural ingredients and poses no health hazards.

The companies announced the effort in a YouTube video explaining the background of their symbiosis.

More Innovation

This type of thrift is not unusual in Japan, a country that reuses as much as possible (including using old bath water for doing laundry). The partnership is not necessary a sustainability effort; however, I think that repurposing, rather than discarding, a plastic container has an environmentalist ring to it.

In recent years, this seems to be an increasingly pertinent issue in Japan. The 2020 Olympics, until they were sadly postponed, were intended to be a green event. More and more artisans are focusing on traditional and environmentally friendly means of making their designer products. Even reusable metal straws have made the scene.

The METI Journal, a publication by the Ministry of Economy, Trade, and Industry, recently reported on the progress of developing marine biodegradable plastics bags taking place in Japan. As disposable plastic bags are increasingly discouraged, innovations in the area could be wide-reaching.

Fukusuke Kogyo, a plastics manufacturer, and Gunma University professor Kenichi Kasuya have recently developed a biodegradable plastic product. While certification appears likely but is still pending, the product largely dissolves in seawater over six months. If approved, the product could be used in plastic bags. Toppan Printing Co., alongside GSI Creos Corp, is also working on a similar product that can be incorporated into bags and cutlery.