Source: Murakami Kaimeido

Japanese company develops “floating image” no-touch touch panels to avoid direct button contact

- Tags:

- coronavirus / COVID-19 / Futuristic / Japan / Technology

Related Article

-

Bare gruesome fangs and more with Japanese designer’s awesome creature masks

-

Newest Japanese Kit Kats Are Premium Birthstone Chocolates To Be Sold Monthly

-

Sushi Cola And Sweet Sake Flavored Cream Puffs And Shaved Ice Make Summer Splash In Japan

-

90-Dollar Tissues Let You Blow Your Nose With All The Colors Of The Rainbow

-

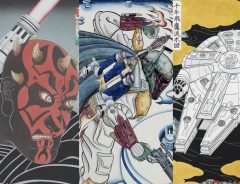

Ukiyo-e Star Wars Prints Give The Force A Boost With Traditional Japanese Artwork

-

Moving LEGO Sushi Bar Has Chef With Katana and Astronauts Downing Beer

Response to the spread of the coronavirus as an ongoing global pandemic has seen not only a focus on social distancing, but extra caution exercised when coming into contact with commonly shared public items such as door handles, rails, and especially buttons.

The development and proposed mass implementation by makers in Japan for a new "floating in the air interface", which has many on social media comparing it to science fiction-esque hologram imagery, may help in regards to the button problem, at least.

The new development is the braindchild of Shizuoka-based Murakami Kaimeido, an automotive parts manufacturer specializing in mirror technology, and Parity Innovations, a development venture company in Kyoto Prefecture. The two have developed what they are calling "Floating Pictogram Technology", an innovation that would install non-contact interface system for commonly used panels in elevators, ATMs, and public restrooms.

(Many public Japanese restrooms have touch panels for flushing, washlet control, water pressure, and a number of other functions.)

The concept would implement a highly visible airborne image system with a sensor so that users could simply hover their finger above the floating image of a button, avoiding actual physical contact.

Murakami Kaimeido already started providing samples for practical use, and is aiming for mass production in 2022 while making improvements.

The concept behind the developed system was put together as a response to the coronavirus pandemic, but now has legs as a practical implementation in a post-coronavirus world--with some nifty imagery to boot.